- Дом

-

Товары

-

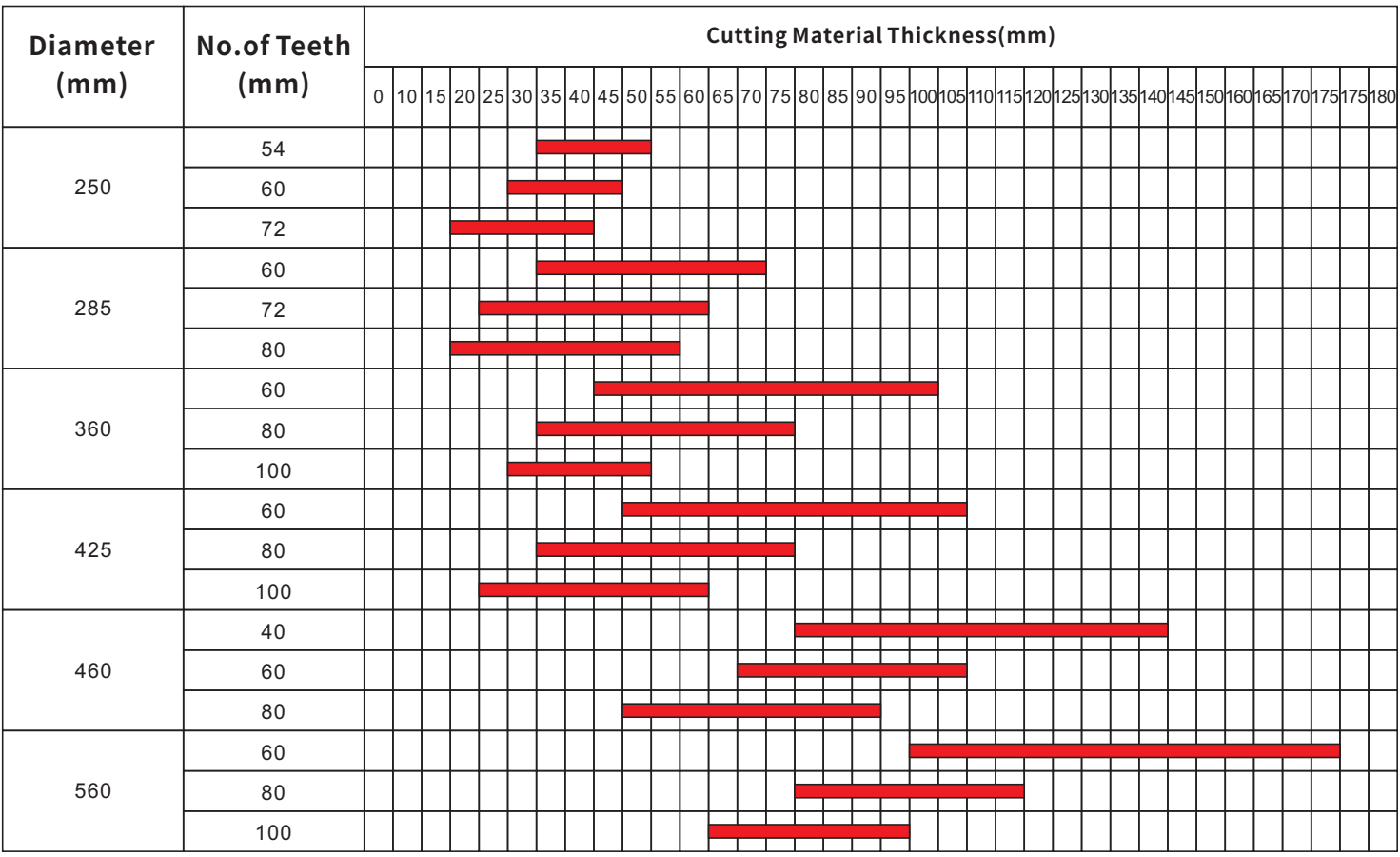

Пильный диск для резки дерева

Пильный диск для резки дерева

-

Холодная пила для резки стали

Холодная пила для резки стали

-

Пильный диск для резки алюминия

Пильный диск для резки алюминия

-

Фреза для предварительного фрезерования PCD

Фреза для предварительного фрезерования PCD

-

Сверло

Сверло

-

Бит маршрутизатора

Бит маршрутизатора

-

Панельный резак

Панельный резак

-

Строгальные ножи

Строгальные ножи

-

Держатель цангового патрона

Держатель цангового патрона

-

Шлифовальный круг

Шлифовальный круг

- Универсальный пильный диск

- Пильный диск для кромкооблицовки

- Пильный диск для форматирования панелей

- Регулируемая подрезная пила

- Коническая подрезная пила

- Пильное полотно Milti с граблями

- Пильный диск

- Пильный диск для одиночной стружки

- Пильный диск с тонким пропилом

- Холодная пила для резки стали

- Холодная пила для резки высокоуглеродистой стали

- Холодная пила для резки труб

- Холодная пила для резки нержавеющей стали

- Холодная пила для ручного устройства

- TCT пила для резки алюминия

- летающая пила

- Салатное сверло

- Сверло с квадратным отверстием

- Врезной резак

- Дрель для дюбелей

- Сверло для сверхмощных дюбелей

- Шарнирное сверло

- Ступенчатое сверло

- Ступенчатое сверло

- Сверло сквозного отверстия

- Бит для гравировки

- Врезная бита

- Профильный резак

- Резак для суставов пальцев

- 1/4 угловой круглый резак

- Полукруглый резак

- Канавочный резак

- Резак дверной рамы

- Резак для дверных досок

- Кромкооблицовочный станок

- Шипорез

- Спиральный режущий блок

- Регулируемая фреза для канавок

- Резак для дверей шкафа

- Строгальный станок со сменным лезвием

- Строгальные ножи типа HSS

- Твердосплавные ножи для рубанка с инкрустацией

- Реверсивные твердосплавные вставки

- Скребковое лезвие для кромкооблицовочного станка

-

- О нас

- Скачать

- Присоединяйтесь к нам

- Cвяжитесь с нами